Prototypes

Easily obtain design feedback and validation by harnessing the power of top-tier prototype tooling. Craft small batches of plastic molded parts with exceptional injection molding prototypes that meet the highest standards. Our proficiency lies in rapid prototype mold manufacturing, ensuring you receive functional prototypes for rigorous testing and market validation. Leveraging cost-effective aluminum tooling, we empower you to mitigate financial risks before committing to full-scale production.

production

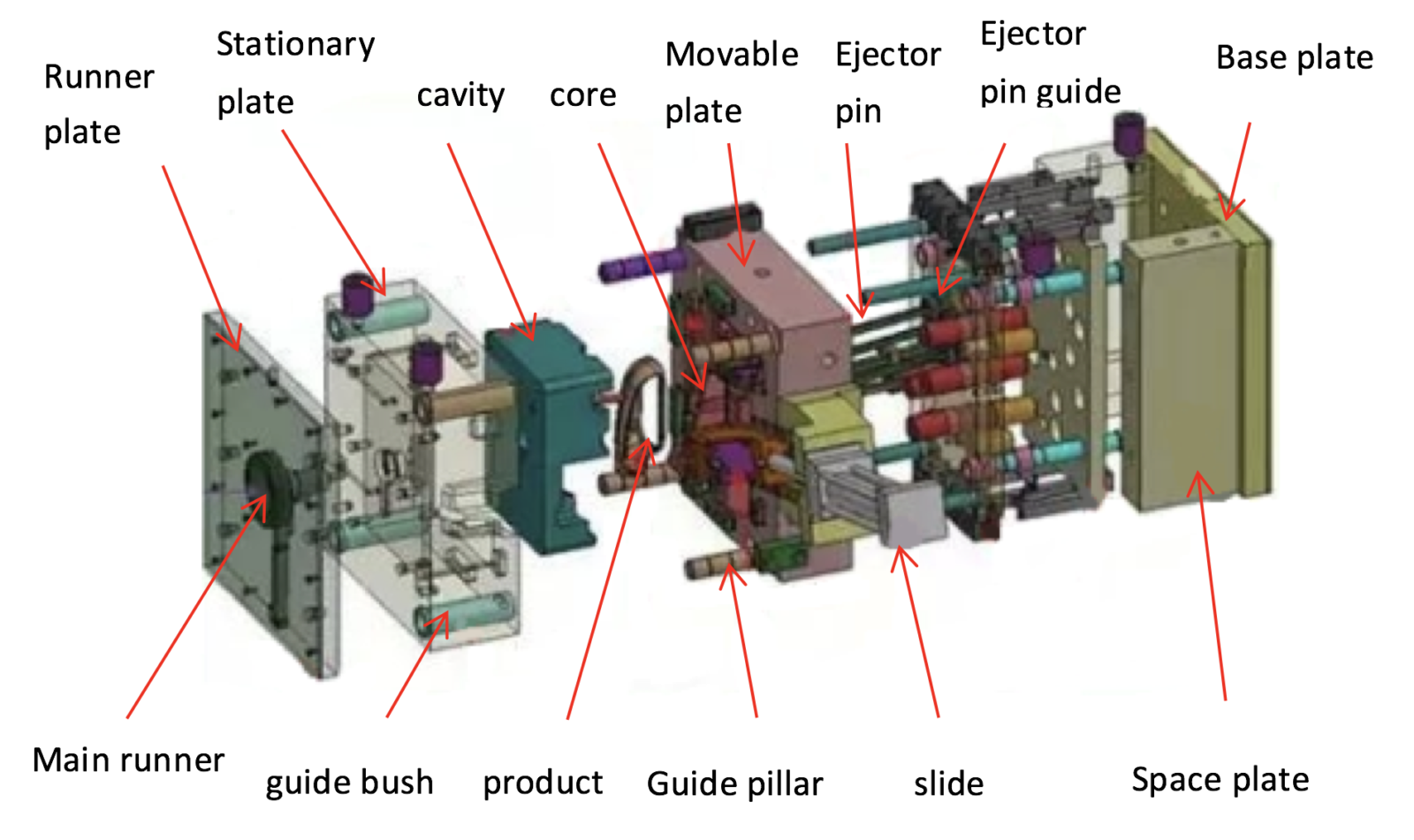

Our expertise lies in crafting top-tier production molds tailored for high-volume plastic part manufacturing. Forging these molds from high-strength, long-lasting tool steel materials ensures their capability to churn out hundreds of thousands of parts with unwavering precision and durability. Furthermore, we possess the flexibility to adapt materials and construction techniques to match your distinct specifications and needs.

中文

中文